Thermal Potting

Shenzhen Tensan is a professional manufactures of Thermal Grease. There may be a lot of Thermal Grease manufacturers out there, but not all Thermal Grease manufacturers are alike.Our professional expertise in manufacturing Thermal Grease has been honed over the past 10+ years.

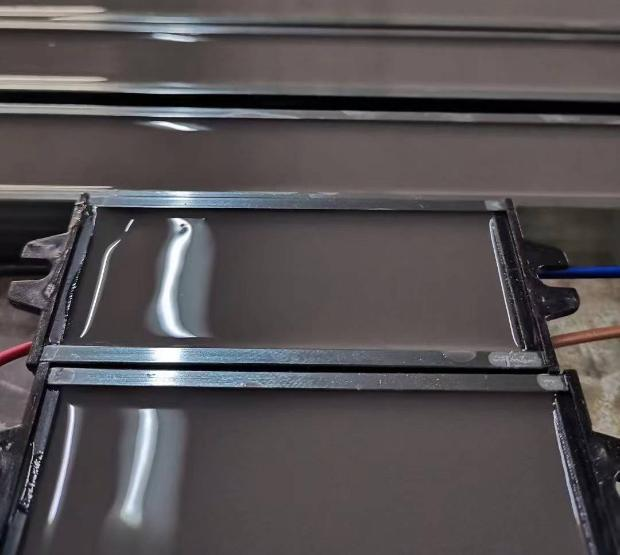

Thermal potting is suitable for general potting material for power supplies, connectors, sensors, industrial controls and transformers.

Termal potting Two-part, 1 to 1 mix, dark gray, general purpose encapsulant with good flowability and flame resistance.> Excellent Heat Resistance Silicone Encapsulant Waterproof> Heat Conductive Potting Silicone> Silicone Potting for LED Driver

Read More Thermal Grease

Shenzhen Tensan is a professional manufactures of Thermal Grease. There may be a lot of Thermal Grease manufacturers out there, but not all Thermal Grease manufacturers are alike.Our professional expertise in manufacturing Thermal Grease has been honed over the past 10+ years.

Thermal grease is suitable for use as an interface material for a variety of mid to high end PCB system assemblies. Tensan thermally paste are grease like silicone materials, heavily filled with heat-conductive metal oxides. This combination promotes high thermal conductivity, low bleed and high-temperature stability. The compounds are designed to maintain a positive heat sink seal to improve heat transfer from the electrical device or PCB system assembly to the heat sink or chassis, thereby increasing the overall efficiency of the device.

> Silicone-based Thermal Paste with Good Insulation for Consumer Electronics> Excellent Heat Conductivity Thermal Paste Compound for Laptop CPU> Thermal Paste Heat Transfer for LED Bulb

Read More Thermal Pad

By using a special process, Tensan thermal pad use the silicone as the base material, adding thermal conductive powder and flame retardant together to make the mixture to become thermal interface material. Tensan thermal pad is effective in lower the thermal resistance between the heat source and the heat sink.

> Soft Silicone Type Thermal Mat/Thermal Pad for Electronics TS300

Read More Electronic Silicone

High performance neutral cure electronic silicone adhesive/sealant,One-part adhesive/sealant • Cures at room temperature when exposed to moisture in the air • Alkoxy cure system • Non-sag, paste consistency • Easy to apply • Cures to a tough, flexible rubber • Excellent adhesion to many substrates.

> Black RTV Silicone Sealant> Widely Used RTV Adhesive

Read More

About Us

Latest News

- 26/12/2025

Applications of Silicone Sealants: Effective Bonding of Various Materials

Read MoreSilicone sealant is a high-performance bonding and sealing material widely used in many fields. It can bond a variety of materials, including but not limited to glass, metal, ceramics, plastics, concrete, and wood. Silicone sealants have excellent high and low-temperature resistance, weather resistance, water resistance, and elasticity, making them suitable for various indoor and outdoor environments.

- 25/12/2025

What are the advantages of silicone potting? What should you pay attention to when buying potting?

Read MoreSilicone potting compound is a potting material with organic silicon polymer as the main component, and it has the following significant advantages:

- 22/12/2025

Silicone Potting: The Core Guardian of Electronic Equipment Stability

Read MoreIn today's rapidly developing electronics industry, Silicone Pottings have become a key material for ensuring the stable operation of electronic equipment. With their superior comprehensive performance, they build an all-around protective barrier for various precision electronic components.