Thermal Paste Heat Transfer for LED Bulb TS1006 Features & Benefits Thermal Paste Heat Transfer for LED Bulb as the heat transfer medium of electronic components and lighting assemblies, use to reduce operating temperature of the heating element. REACH, ROHS certified High thermal conductivity Good temperature resistance

Features & Benefits of Thermal Paste Heat Transfer for LED Bulb TS1006

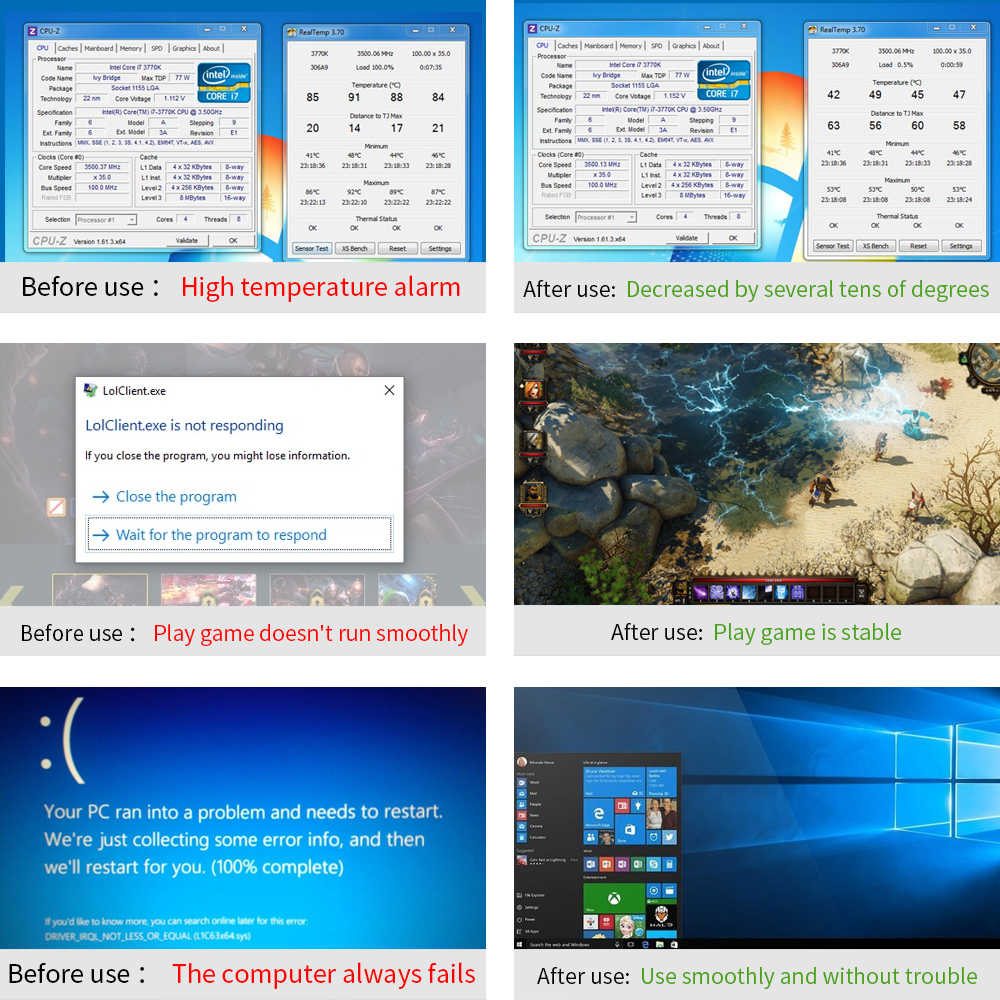

Thermal grease,as the heat transfer medium of electronic components and lighting assemblies, use to reduce operating temperature of the heating element.

◆ REACH, ROHS certified

◆ High thermal conductivity

◆ Good temperature resistance

Application of Thermal Compound Paste Heat Transfer for LED Bulb TS1006

◆ Lighting assemblies

◆ Telecom equipment

◆ Consumer electronics

◆ Power supplies

◆ Power components for transportation

Description of Thermal Paste Heat Transfer for LED Bulb TS1006

Thermal heat paste is a kind of gray paste organosilicone compounds. This product has good thermal conductivity and dielectric properties, weather resistance, pollution resistance,

anti-ultraviolet property and excellent moisture-proof insulation property. This product is suitable for thermal coating of electrical appliance and electronic products which is easy to use.

Packing Information of Thermal Compound Paste Heat Transfer for LED Bulb TS1006

1. Hard plastic tube 1KG

20cans / carton

2. Hard plastic tube 2600ml

4 tubes / carton

Storage andValidity of Thermal Paste Heat Transfer for LED Bulb TS1006

Stored in room temperature, and in a cool, ventilated, dry place.

Shelf life: 12 month

Typical Properties of Thermal Compound Paste Heat Transfer for LED BulbTS1006

|

Item |

Index |

|

Appearance |

Gray |

|

Specific gravity( g/cm3) |

2.3 |

|

Viscosity( cP ) |

82000 |

|

Complete cure time 25℃(H) |

24 |

|

Thixotropy |

1.68 |

|

Thermal resistance at 40 psi(℃-cm2/W) |

0.06 |

|

Temperature range( ℃ ) |

-45 ℃ ~ 200 ℃ |

|

Volatile component(150℃/4H) |

0.02% |

|

Volume resistivity ( Ω.cm3 ) ≥ |

1.3×1013 |

|

Dielectric strength( KV/mm ) ≥ |

1.89 |

|

Thermal conductivity(/W/m.K) |

2.5 |

|

Dielectric constant@1 kHz |

14.0 |

How Can We Help You Today

Tell us about your performance, design, and manufacturing challenges. Let us put our silicone-based materials, expertise, application knowledge, and processing experience to work for you.

For more about our product, please visit: