As thermal interface materials commonly used in electronic products, both thermal grease and thermal pads can be used for heat dissipation components to improve the operating speed, reliability, stability and service life of electronic devices, and are an indispensable part of electronic products.

Generally speaking, in order to increase thermal conductivity, customers tend to have high thermal conductivity when choosing thermal interface materials. So when the thermal conductivity of the two is the same, how to choose?

At this time, it should be considered from the aspects of material properties, application objects, and usage methods:

Material characteristics:

The two components are different, and the material properties are different. In the face of some special application requirements (such as no siloxane volatilization, shock absorption, insulation, etc.), different thermal conductive materials are often used.

Thermal Grease

Low oil separation (tend to 0), long-acting type, good reliability, strong weather resistance (high and low temperature resistance, moisture resistance, ozone resistance, aging resistance, etc.), good contact surface wetting effect, effectively reducing interface thermal resistance, etc.

Thermal Pad

Double-sided self-adhesive, high electrical insulation, good temperature resistance, high flexibility, high compliance, low compression force applications, and high compression ratio.

Application object

These two thermal conductive materials can be widely used in parts of various industries, such as: power supply, mobile phones, LED, automotive electronics, communications, computers, home appliances and other industries. Therefore, for different electronic components, the corresponding ones should be selected according to their characteristics. Thermal interface material.

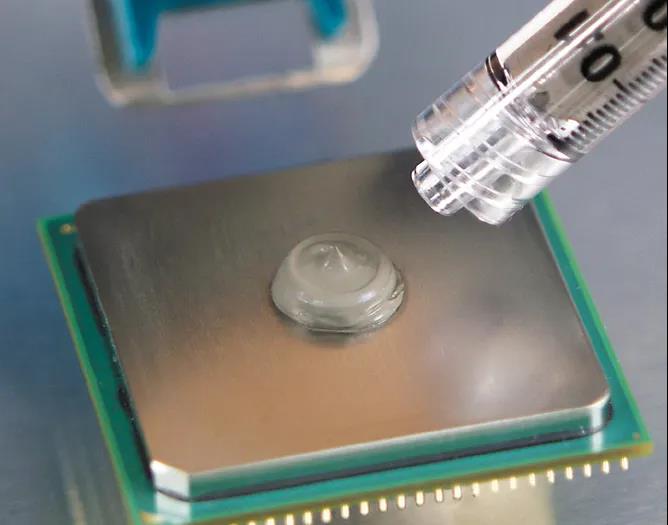

Thermal Grease

A paste-like product with high thermal conductivity, a thermal interface material that can effectively reduce the contact thermal resistance between the heat source and the radiator.

Mainly used in heating elements such as CPU, transistor, thyristor, IGBT module, LED lamp, etc.

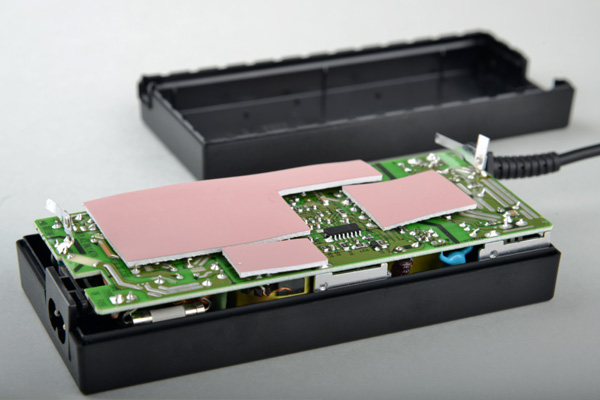

Thermal Pad

Thermal interface material with a certain thickness, compressibility, resilience, double-sided self-adhesive, and high compliance.

Mainly used in IC, transformer, inductor, capacitor, PCB board and other heating elements.

For different application objects, the use of thermally conductive materials will be different.

Thermal Grease

Clean the application surface first, then stir the silicone grease evenly, and then apply the silicone grease to the surface by dot coating, brushing or screen printing. If screen printing is used, it is recommended to use 60-80 mesh nylon screen, and a rubber scraper with a hardness of about 70. When coating, apply silicone grease at about 45 degrees to the coated surface. After the operation, unused products should be sealed and stored in time.

Thermal Pad

To keep the surface of the component clean, first remove one of the protective films. Stick the thermal pad on the surface of the component, then tear off the protective film on the other side, and press the heat sink (or shell) on the thermal silica gel sheet to tighten.

In general, thermally pad and thermally grease have their own merits.

When choosing, you need to take into account factors such as the application object, ease of operation, and material characteristics to make the best choice.